- 6

- 92 580

Glen Hodgkinson

Приєднався 5 тра 2012

Відео

M Level 3 P8 Project (Day 1)

Переглядів 3364 роки тому

This video covers the pre-preg repair of a sandwich composite part. This is part of the BCIT M aviation program .

M Level 3 P7 Day 2

Переглядів 4624 роки тому

STEP 2 in the P7 Construction Project. We add a foam core to our lid and build a U-Channel for installation in the P6 Tool box. We get the opportunity to use a Hot Wire for cutting the foam and carry out 2 wet layups for the build.

M Level 3 P7 Day 1

Переглядів 5704 роки тому

Composite construction of a lid for a tool box built as part of the M Level 3 program. We work with fiberglass and carbon fiber to produce a composite product which is formed over a mold.

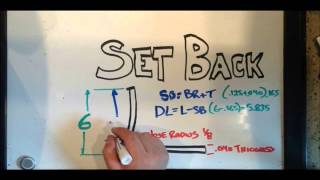

Bending Aircraft Metal 101

Переглядів 90 тис.12 років тому

This video takes you through the basic theory of bending a piece of Aircraft Aluminum over ninety degrees. This presentation is a "Digital Project" in the PID 3240 program, at Vancouver Community College.

Sea Shell Under Spinnaker

Переглядів 49212 років тому

On our way to the 2010 MYCBC Blaine Regatta, and first time with our 1992 MacGregor 26S sailboat under full Spinnaker.

To much gibberish with crayons

This is a great video! thanks so much for the in depth info.

I love this video God bless you ❤

Thank you for this video ! Gonna watch it again and again thank you very much for posting !

You’ve mentioned grain a few times but not how to bend in relationship to the grain, ie across or with.

Thanks! I haven't done this in 4 years, and just got hired lol.

Your information on the sight line is simply wrong.

Well taught

This is a great well presented presentation on the subject of sheet metal bending.

God bless you for this information, my instructor isn’t good at teaching. He gets mad too whenever asked a question...

finally found clean concept

Thanks for the simple explanation. Very easy to follow.

4:59 don't you mean 5.835? That's what it says on the diagram

Good catch lol

Can I get your heart Mr. H?

Dude WTF man 😂😂😂

Thank you very much for such amazing information you have shared, it is really helpful... I'm waiting for more video :)

why isn't the bend allowance and your sight line distance not the same thing??

great video. Really simplified the bending layout calculations for me. But what i cant find anywhere is how do you or how do you determine which side to measure the sight line from or is it just which side do you prefer

Cant finds either

This really helped a lot studying for my practical. Thanks!

this way of explaining was better than my training we kept asking what is set back and the instructor at that time could not explain in a way that we as a student understood and he would call the class hackers which we replied with we are as good as our instructor so if we are hackers our instructor is a better hacker because he trained us

Here, I'll fix it for you: "thiswayofexplainingwasbetterthanmytrainingwekeptaskingwhatissetbackandtheinstructoratthattimecouldnotexplaininawaythatweasastudentunderstoodandhewouldcalltheclasshackerswhichwerepliedwithweareasgoodasourinstructorsoifwearehackersourinstructorisabetterhackerbecausehetrainedus"

Sorry but I think you ought to get out of teaching and see a shrink.Absolute rubbish.

nize that goof

Best vid I’ve seen for this! Thansk

you need to have it annealed first or buy it in {O} condition in order to bend it.

you cant bend heat treated aluminum it will crack

You never bent a piece of metal in your life lol

Nice video very helpful and easy to understand

Who else is trying to understand this bull for Paul C class?

I was hoping you would have posted more. Trying to prepare for my practical and its frustrating when you can't actually practice any of the hands on stuff.

Please America, start using the metric system. It's way easier.

Philip Barker M

No

Very helpful! Prepared for tomorrow

Thank you! this explanation really simplified what I could not understand in the class. I have to start a four sided box tomorrow out of one sheet of metal. Will I have to take each total from the Developed Length calculation and multiply by 4 to have enough material for all four sides??????? Thanks for any help you can provide

I hope you are not a sheet metal instructor cause you made that shit 100 times harder than it is and gave a lot on unnecessary bullshit!!! Please stop!

Thank you for this video it helped me alot :)

very helpful and well done,

After thirty years of messing with aircraft, I have yet to come across a real world problem that required me to figure out bend allowance and set back. Bend the thing, then trim it! I think it was invented by the FAA just to be obnoxious.

After thirty years you probably wasted several metric tonnes of metal with your technique

@@MadDeuceJuice Several cubic inches, yes. The upside is perfectly fitting parts.

@@MadDeuceJuice everyone’s a CRITIC 🙄 😂JK You’re prolly correct though. As a pilot I need parameters and the same is true being a mechanic. I’d rather know how than not to know how. Also I’m a 4 year A&P apprentice who just got his 8610-2 and I need to know for my test. THANKS FOR POSTING THIS ! Liked and subbed !

Thank you for this video. It helped me a lot. :)

thank you i have my aircraft sheet metal test this morning. please explain the K factor in your next class

Easier to follow than the AC65-15A. thanks

titays

you look like a fabian gavin

Love the video and that must be a very fast Classic. I bet you beat many M and X's in your time! Nice looking Spinnaker!